When customers ask about our Formaldehyde (Aldehyde) Monitor, the 571, we know this chat is going to go well.

The Easy Sell

We have the best formaldehyde badge in the business. It’s just a matter of deciding which topic to address first:

- Superior Chemistry

- Very low method reporting limit: 0.1 μg.

- Long sample holding time: 28 days.

- Large capacity: over 16 times the OSHA PEL.

- Wide range of uses:

- Use for 15 minutes for OSHA STEL,

- 8 hours for OSHA TWA,

- and Indoor Air Quality monitoring (24 hours, 48 hours…)

- Ease of Use:

- Pop open and snap shut. No transfer of caps or fuzzy sampling times.

- Small, the size of a quarter.

- No refrigeration required before or after sampling.

- Low Background: Assembly in 100% nitrogen.

- Synergy: One call and you are talking to the badge manufacturer and the lab.

- Fantastic Price: Pay for both the badge and analysis together, saving time and money.

Superior Chemistry

Excellent Reporting Limit allows for the 571 badge to be used for STEL monitoring

Many future customers use a badge that utilizes a colorimetric method that works perfectly well… except that the method reporting limit is about 10 to 30 times higher (depending on the lab you use). So, even with a very fast sampling rate, these badges are not sensitive enough to be used for STEL monitoring.

If a project calls for collecting 15-minute samples, users of less sensitive badges had better remember to calibrate a pump and bring the glass tube crackers. Or, they can bring Assay Technology 571 badges and know they can monitor for STELs, TWAs, and even Indoor Air Quality, because the 571 can do it all.

Here are the reporting limits for formaldehyde on the 571:

- 8 hours: 0.01 ppm (OSHA PEL: 0.75 ppm)

- 15 minute: 0.34 ppm (OSHA STEL: 2 ppm)

Our analytical method gives a STEL (15-minute) reporting limit almost 6 times lower than the OSHA short term limit. As a result, you can buy a box of 571 badges and use them for either short-term or long-term sampling. Forget about the hassle of breaking glass tubes and calibrating sampling pumps.

Stability

The 571 uses DNPH chemistry to collect aldehydes. Under acidic conditions, the wafers are treated with DNPH and phosphoric acid, DNPH reacts with the aldehyde and creates a stable derivative. Therefore, after use, the holding time is 28 days with no refrigeration required. (Note: You may refrigerate the badges. Also, it is always a wise idea to send any media for testing back to the lab as soon as possible).

Capacity

The capacity of the 571 badge is 12.5 ppm for an eight hour day, 16 times the OSHA PEL (12.5 ppm /0.75 ppm). If you are worried about having a result as high as 12.5 ppm, then you are probably wearing a self containment suit in this work area.

Indoor Air Quality Monitoring

The sample stability, combined with the high capacity, means that the 571 badges are perfect for Indoor Air Quality testing.

Since the badge samples are stable for 28 days at room temperature, formaldehyde collected in the first few minutes of sampling will not reverse diffuse off the badge as it sits out for the typical IAQ sampling time of 1 to 3 days.

Since the capacity for 8 hours is 12.5 ppm, the capacity for 24 hours is 1/3 of that or 4.2 ppm, over 4 times the OSHA PEL. The badge still has plenty of capacity for long duration sampling, since IAQ levels are usually in the ppb range.

Ease of Use

The badge is small, about the size of a quarter. It’s also very lightweight; you will forget it is on. Here’s a link to a short slide show explaining how to use them. Essentially, you will:

- Pop open the badge

- Clip it to your collar

- When you are done, snap it shut.

- Reseal it in its air-tight pouch, complete the paper work, and that’s it!

Low Background

As both a media manufacturer and an analytical lab, one term we get a lot of questions about is “blank”. Whether you have a field blank or media blank, when you use the word “blank”, it comes with a certain expectation that it must have zero of the chemical of interest in it or the data is “wrong”. That is not true at all.

So far, it is impossible to obtain a bottle of DNPH without it already containing a small amount of formaldehyde. As a result, there has never been a DNPH badge or cassette or tube with zero formaldehyde on it. A better term would be “background.” Labs are allowed to subtract out the media background and customers are allowed to correct for field background levels of formaldehyde, as well.

However, it is important that the background be low and consistent. If your reporting limit is 1 μg and the background average is 10 μg with a standard deviation of 5 μg, that is not good.

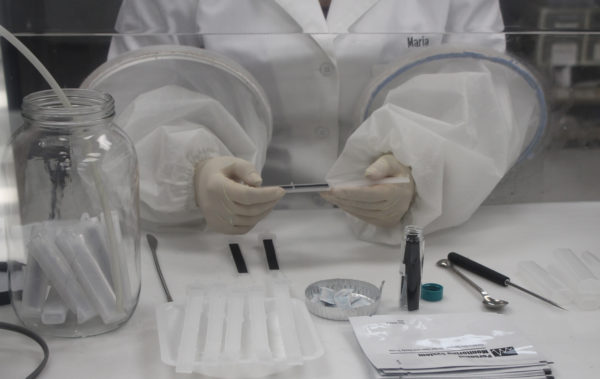

Assay Technology spends a lot of effort to keep backgrounds as low as possible. This is a challenge. If we made the badges out in the open air, there is enough formaldehyde present to produce background levels that would be both high and variable.

In order to precisely control background, we manufacture every aldehyde badge under a blanket of nitrogen. The normal indoor air we breathe is pushed out of the glove box, and clean formaldehyde-free nitrogen is pushed in, making the average background of formaldehyde about 0.03 μg or 0.0031 ppm worth of formaldehyde when using for 8 hours. Our Quality Control team is always tracking and correcting for this tiny amount of background for each specific manufacturing lot.

Synergy: All-in-One Benefit

Using our badges together with our labs, there are two significant benefits:

- When you buy the badge and analysis together, it is easier on us, so we give you a fantastic price. You also receive the benefit of only one billing event and one interaction. It is easier on you, easier on us, and you save money.

- Assay Technology controls both the badge and the analysis. If you have a question about the result, we could never shrug our shoulders and say, “The analysis looks good. Must be a badge problem. Call the badge manufacturer.” Or vice versa. We will have all the information to review with you.

If you ever have a question, contact us. We have an amazing Customer Service team ready to help!